Putting everyday computer parts to space radiation test

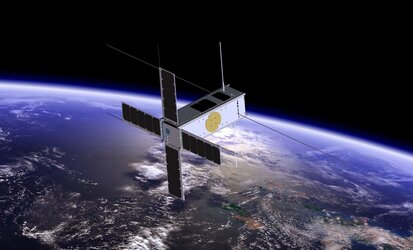

ESA’s next mission, the miniature GomX-4B, includes a piggyback experiment to test how well everyday commercial computer memories perform in the radiation-soaked environment of space.

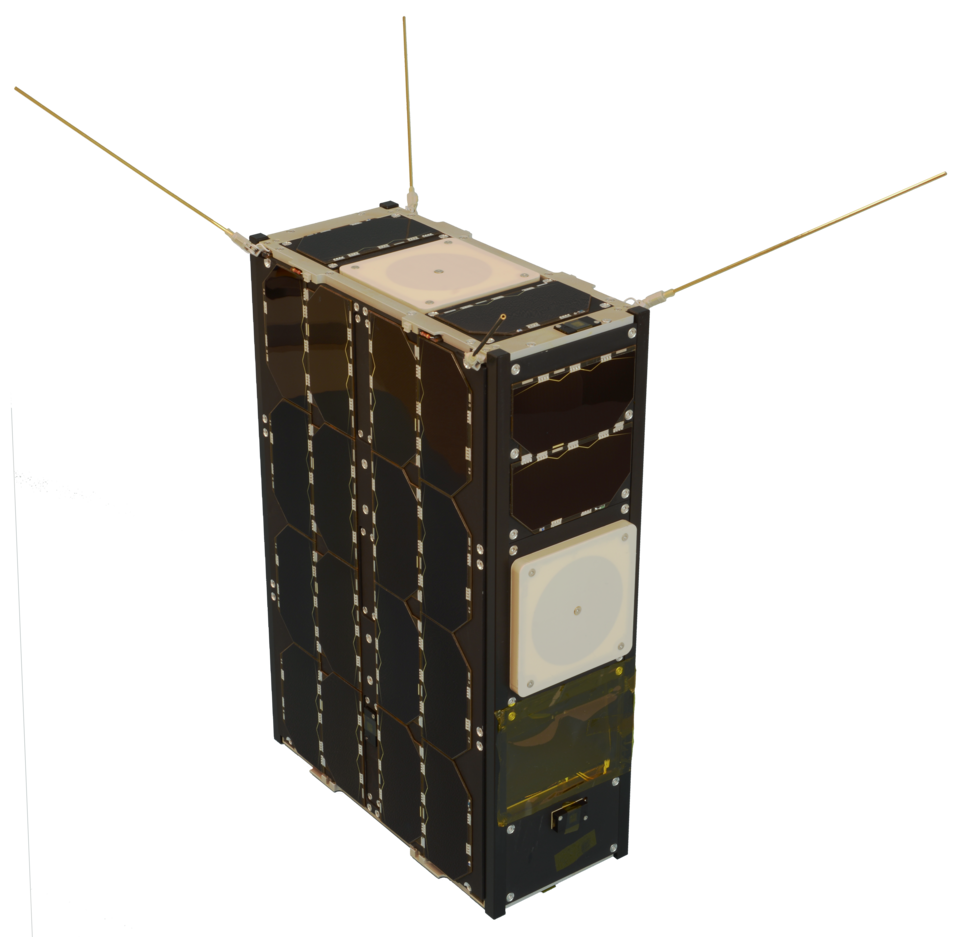

Ready to be launched from China this Friday, GomX-4B was built from six standard 10 cm CubeSat units by GomSpace in Denmark.

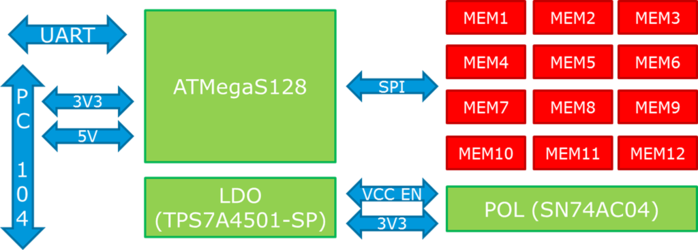

Its main goal is to test radio links between satellites and micropropulsion, but GomX-4B also carries a small, cheap but important secondary experiment: a single 10x10cm electronics board with 12 computer flash memories, made up of three examples of four different types, each purchased for a few euros.

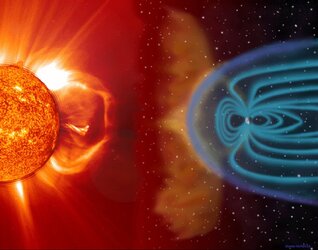

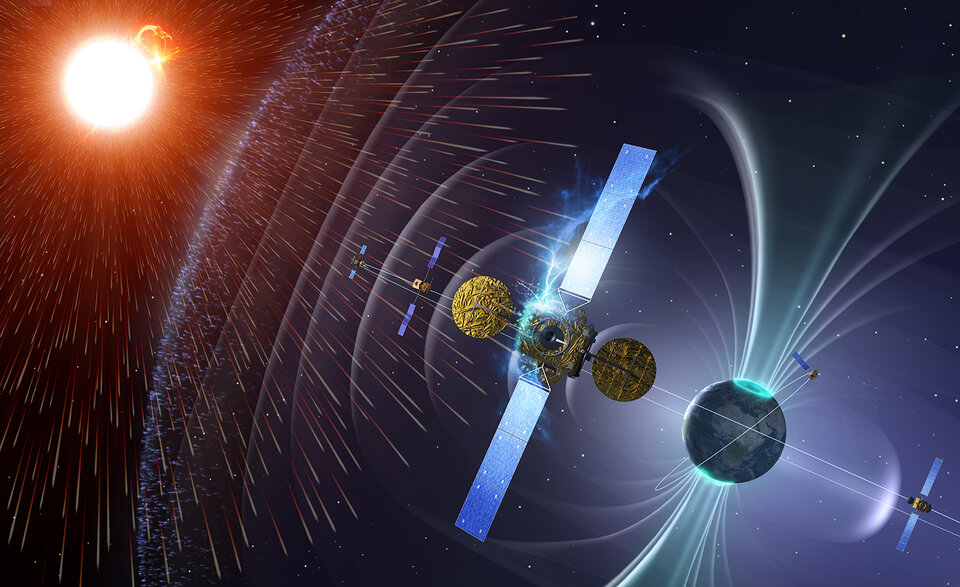

Known as Chimera, this experiment will test how such ‘commercial-off-the-shelf’ parts cope with bombardments of high-energy electrically charged atomic particles from the Sun and deep space. A specially space-qualified monitoring chip will record the performance of the dozen memories.

“Interaction with charged particles can induce ‘bit flips’ in computer memory, introducing errors,” explains Chimera team member Tomasz Szewczyk.

“We perform ground testing and software modelling to understand how different components are affected by radiation, but nothing beats real testing in space.

“There’s an increasing push to use more off-the-shelf parts in orbit because they are theoretically cheaper and more capable than space-designed parts, but there are question marks over their reliability.

“For instance, different batches of the same part may have radically different reactions to charged particles, based on small variations in the raw materials or the manufacturing process. That’s why we are flying three versions of each memory.”

Once it became clear there was a chance to fly on GomX-4B, Chimera was built and tested in a year, with ESA’s data engineers working together with quality assurance experts. The board was assembled by certified ESA engineers, with environmental testing for launch and space conditions using shaker tables and thermal–vacuum chambers.

“ESA missions have already been using a lot of different off-the-shelf parts, certainly across the last two decades,” comments computer scientist Gianluca Furano. “All the mass memory of currently flying missions is made up of purely commercial flash devices, for instance.

“And right now there are some component areas where we simply don’t have any space-qualified alternative. The problem is that off-the-shelf parts need to undergo a lot of testing in order to be sure they’ll meet the necessary performance and reliability, and this can mean their per-unit cost actually ends up much higher.”

In addition, the capabilities of space-qualified parts typically lag several generations behind off-the-shelf parts, which benefit from the doubling of transistors per chip every two years or less.

One approach is to take commercial devices and devise methods to best use them for space applications, often with the help of manufacturers. For instance, programmable chips known as called ‘field programmable gate arrays’ can have error detection and correction mechanisms added.

“The more knowledge we have of how these parts behave in space operations, then the more we can develop effective countermeasures,” adds Gianluca.

“Terrestrial industry is becoming interested in such solutions as well. For large data centres using massive amount of memory, cosmic rays already set reliability limits. Such effects will also become a factor within chips for safety-critical applications, such as self-driving cars.”

“Flying technology experiments on CubeSats is opening up a plethora of opportunities to access space faster, and more cost effectively,” adds ESA’s Ali Zadeh. “The multidisciplinary nature of such experiments result in exciting collaborations across our Agency.”