ESA uses terrestrial rocks to recreate the Moon’s surface

Two state-of-the-art ESA facilities are working closely to develop a simulated lunar environment that will serve as a proving ground for future exploration technologies.

As part of this ambitious project, a group of ESA experts recently travelled to a mine in Greenland – which is operated by Lumina Sustainable Materials – to kick off a collaboration that will result in the provision of terrestrial rock samples with similar properties to material found on the Moon.

The team was made up of scientists from the VULCAN Facility, located at ESA’s site in the UK, and the LUNA Facility, located at ESA’s European Astronaut Centre in Germany.

Both centres, set to be inaugurated during 2024, are supporting the agency’s preparations for a sustainable, long-term human and robotic presence on Earth’s natural satellite.

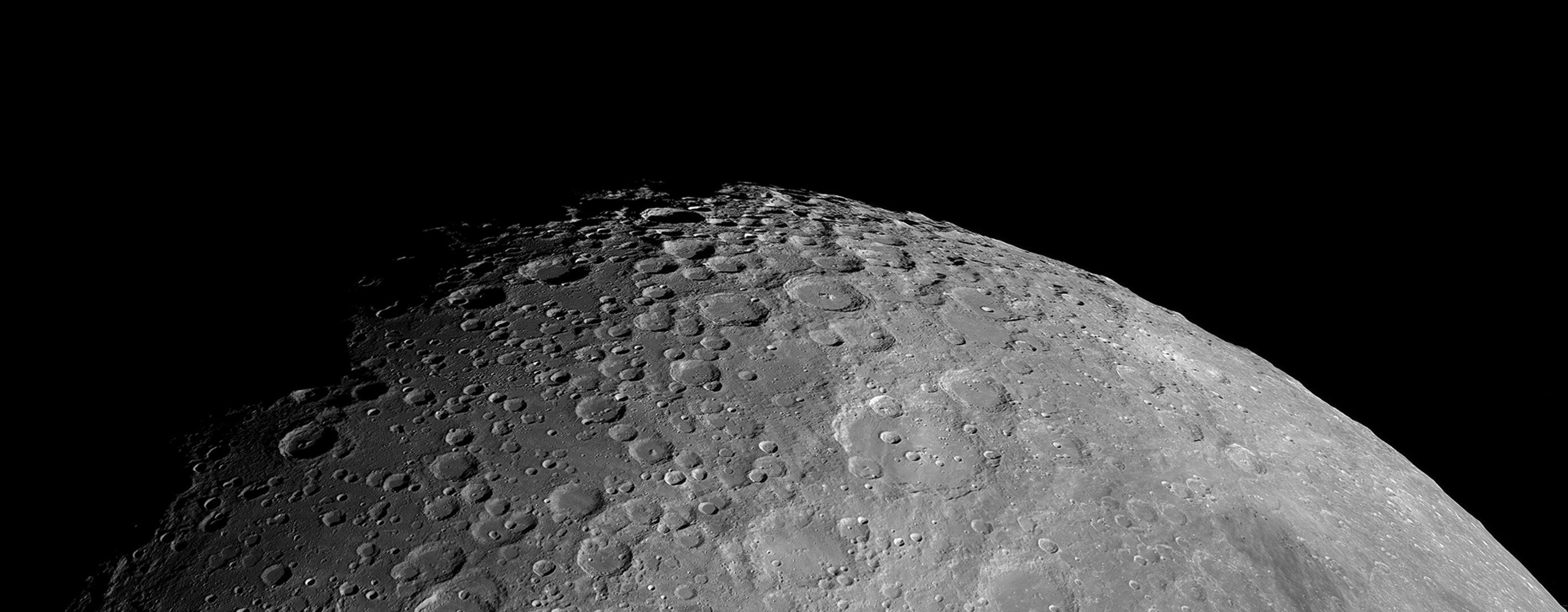

Currently under development with the German Aerospace Center (DLR), LUNA will host a range of cutting-edge facilities including two testbeds that replicate the layer of rock and powdery dust – known as regolith – that blankets the Moon’s surface.

VULCAN is home to a collection of terrestrial samples – or analogues – that simulate lunar regolith and scientists from the facility are using their expertise in geology to support the development of the two LUNA testbeds.

These environments will be used in the development of innovative exploration technologies, including those that employ in-situ resource utilisation to harness local lunar materials to generate oxygen, water and building materials, for instance.

The main testbed is designed to replicate 700 square metres of a lunar mare surface. The other comparatively smaller testbed will simulate a dusty lunar highland environment using about 20 tonnes of light-coloured igneous rock known as anorthosite.

The trip to the Lumina anorthosite mine – completed in October by VULCAN team members Kamini Manick and Aliz Zemeny, along with LUNA team member Aidan Cowley – was key to the ongoing development of LUNA’s facilities.

Lumina employs a unique mining model that ensures no chemical processes are used in its operations, meaning that any waste products can be returned to the natural environment safely.

This approach is of particular interest to ESA and its partners as they work towards developing sustainable in situ resource utilisation strategies for onward lunar exploration.

During their visit, the LUNA-VULCAN trio had the opportunity to examine exactly where and how the anorthosite was sourced and processed, and saw first-hand the complex operations and equipment required to handle the large, dusty volumes.

As well as setting the stage for the procurement of simulant material for LUNA, the trip was important for gaining know-how related to handling dusty regolith and protocols regarding planning, safety and personal protective equipment.

Reflecting on the visit, Aidan said: “It was an enlightening experience to see first-hand Lumina’s profound in-house expertise and rigorous quality control practices. Our discussions quickly expanded beyond the mine’s primary function, touching on its potential for serving as a controlled dusty test environment. Additionally, intriguing research and development opportunities emerged, particularly concerning in-situ resource utilisation.”

Kamini, curator and coordinator of VULCAN, added: “It was a privilege to visit Lumina and open a conversation about what the space exploration and planetary science communities need in terms of regolith simulants. Key to the provision of such analogues is the establishment of a set standards for simulant quality, production, and documentation – VULCAN is at the forefront of this effort in Europe.”